Fire Protection & Kitchen Hood

Fire Protection and Kitchen Hood Suppression

Fire Protection

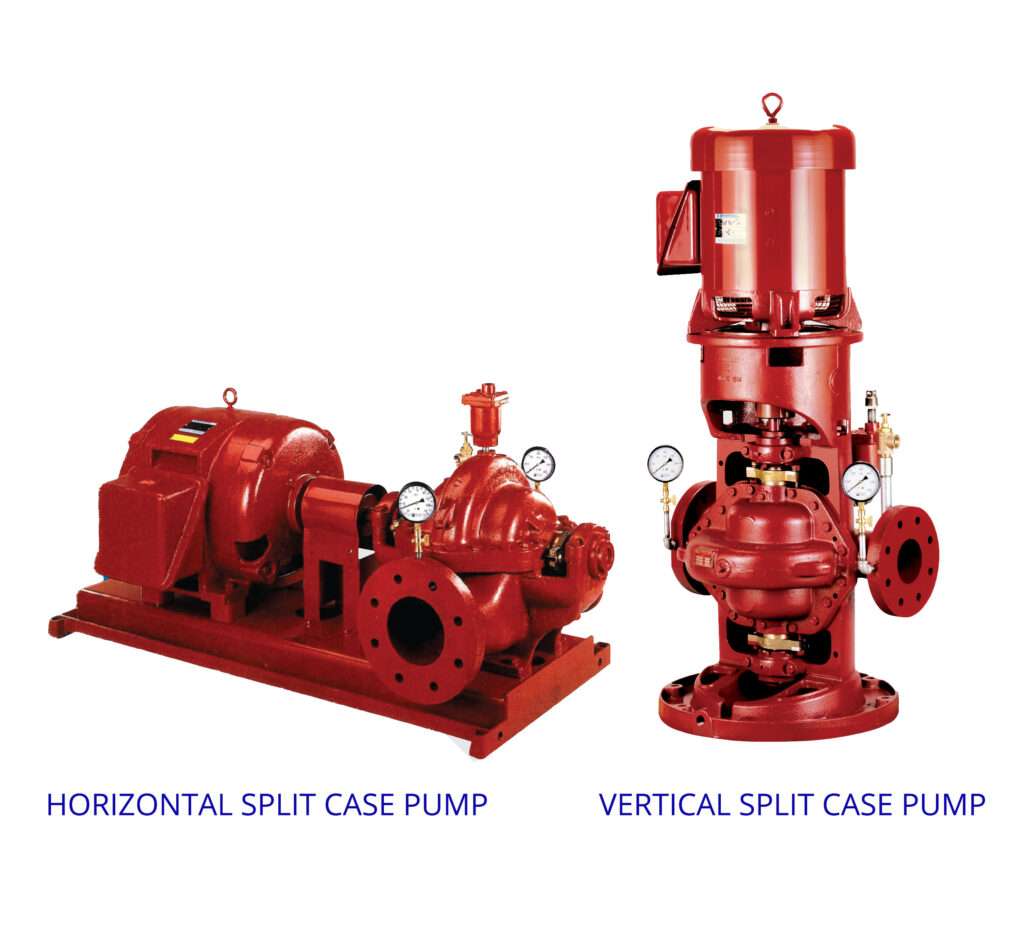

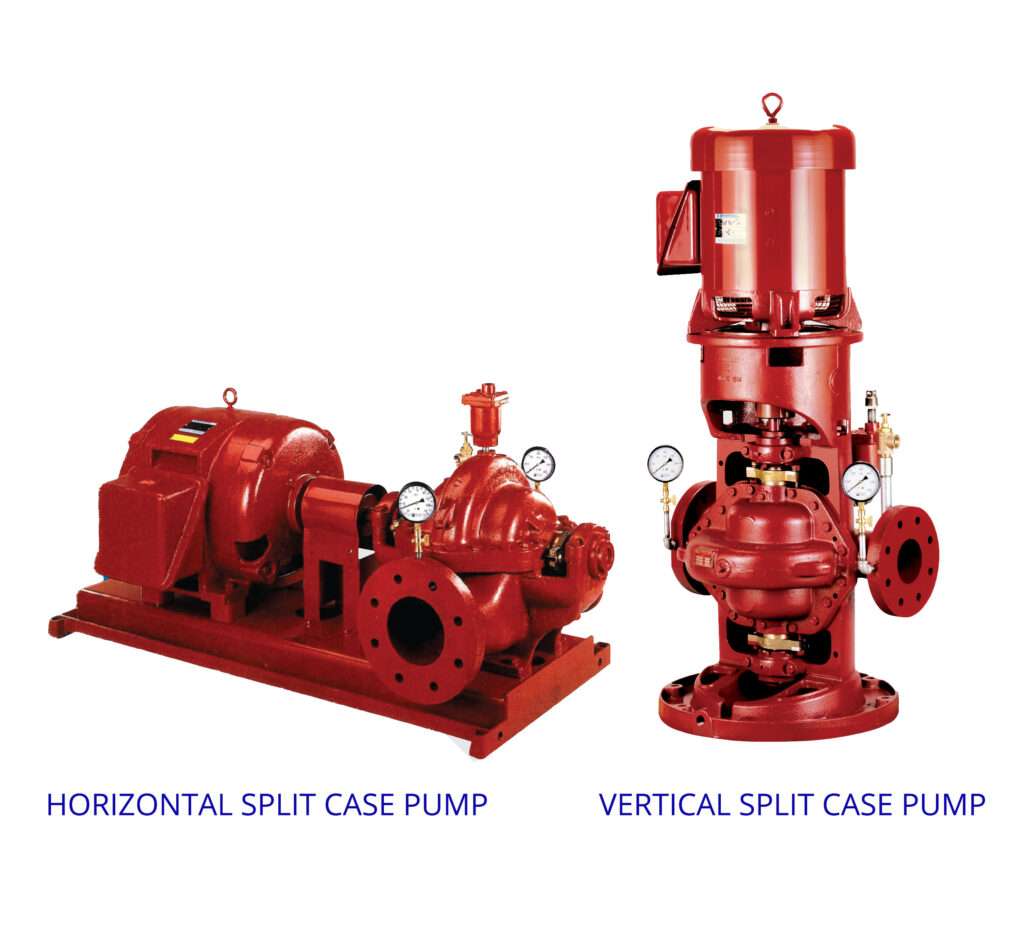

Fire Pumps

- Easy access to all working parts;

- Rugged construction;

- Liberal water passages; and

- Efficient operation.

- Less floor space is required.

- In-line piping arrangement allows piping in any direction in most cases.

- Elevated motor protects against potential flooding if the pump station is in a low area.

- Components are register-fitted to prevent misalignment.

Major parts of fire protection

An alarm check valve is a pivotal component in a fire sprinkler system, designed to prevent backflow and signal the presence of water flow when a sprinkler activates due to a fire. Alarm check valve combines the functions of a check valve and an alarm switch, ensuring that water flows only in one direction while simultaneously activating an alarm when the system is engaged. It helps in maintaining system integrity and promptly alerting building occupants and emergency services of a potential fire.

A butterfly valve is a type of flow control device used to regulate or isolate fluid flow in a pipeline. It features a disc mounted on a rotating shaft, which turns to open or close the valve. When the disc is turned parallel to the flow, the valve is open; when it is perpendicular, the valve is closed. Butterfly valves are widely used in various industries due to their compact design, quick operation, and cost-effectiveness. They are ideal for applications involving large volumes of fluids at low pressures. Upgrade your flow control with our premium Butterfly Valves! Designed for efficiency and reliability, our butterfly valves offer precise regulation and isolation of fluid flow in any pipeline. Featuring a compact design and quick operation, they are perfect for handling large volumes of fluids at low pressures.

A butterfly valve is a type of flow control device used to regulate or isolate fluid flow in a pipeline. It features a disc mounted on a rotating shaft, which turns to open or close the valve. When the disc is turned parallel to the flow, the valve is open; when it is perpendicular, the valve is closed. Butterfly valves are widely used in various industries due to their compact design, quick operation, and cost-effectiveness. They are ideal for applications involving large volumes of fluids at low pressures. Upgrade your flow control with our premium Butterfly Valves! Designed for efficiency and reliability, our butterfly valves offer precise regulation and isolation of fluid flow in any pipeline. Featuring a compact design and quick operation, they are perfect for handling large volumes of fluids at low pressures.

A fire pump is a critical component of fire protection systems, ensuring a reliable supply of water at high pressure to combat fires effectively. Typically powered by electric motors, diesel engines, or steam turbines, fire pumps activate automatically when a drop in pressure is detected in the sprinkler system. They deliver water to sprinklers, hose reels, and other firefighting equipment, helping to contain and extinguish fires in various settings, including commercial buildings, industrial facilities, and residential complexes. Compliance with NFPA standards and local regulations is essential for the proper installation and maintenance of fire pumps, ensuring they function reliably during emergencies.

A fire pump is a critical component of fire protection systems, ensuring a reliable supply of water at high pressure to combat fires effectively. Typically powered by electric motors, diesel engines, or steam turbines, fire pumps activate automatically when a drop in pressure is detected in the sprinkler system. They deliver water to sprinklers, hose reels, and other firefighting equipment, helping to contain and extinguish fires in various settings, including commercial buildings, industrial facilities, and residential complexes. Compliance with NFPA standards and local regulations is essential for the proper installation and maintenance of fire pumps, ensuring they function reliably during emergencies.

A jockey pump is a small but crucial component within a fire protection system, designed to maintain system pressure at an optimal level. It operates continuously, ensuring that the system remains pressurized and ready for immediate activation in case of a fire emergency. Typically, a jockey pump is activated when the pressure drops slightly, compensating for minor leaks or fluctuations, and preventing the main fire pump from cycling unnecessarily. By maintaining consistent pressure, jockey pumps help to prolong the life of system components and ensure reliable performance when needed most. Proper installation and maintenance in compliance with relevant standards, such as NFPA, are essential to guarantee the effectiveness of a jockey pump in safeguarding lives and property.

An inspectors test valve, also known as an inspectors test connection, is a vital component in a fire sprinkler system used to simulate the conditions of a sprinkler activation and to verify the proper operation of the system. It allows for the testing of the water flow alarm and the overall functionality of the fire pump, alarm devices, and associated piping without needing to discharge water through an actual sprinkler head. This testing ensures the system’s readiness and compliance with fire safety regulations. Install an inspectors test valve to maintain fire system readiness and reliability.

An OS&Y (Outside Screw and Yoke) gate valve is a type of valve used to control the flow of liquids in plumbing and piping systems. Its design features an external screw mechanism for smooth operation and easy visual indication of the valve’s position. The gate inside the valve moves perpendicular to the flow direction to either allow or block the passage of fluids. OS&Y gate valves are known for their reliability, durability, and ability to create a tight seal when closed, making them ideal for applications requiring secure flow control, such as in fire protection systems and industrial processes.

A pressure relief valve (PRV) is a safety device designed to protect a pressurized system, such as a fire protection system or boiler, from exceeding its maximum allowable pressure. The valve automatically releases pressure when it reaches a preset limit, preventing potential damage, equipment failure, or dangerous conditions. In fire protection systems, pressure relief valves ensure that the system pressure does not exceed the ratings of pipes, fittings, and other components, thus maintaining system integrity and safety. Ensure system safety and compliance with a reliable pressure relief valve.

A water flow switch is a crucial component in fire protection systems that detects the presence of water flow within the system. When water flows through the switch, it triggers a signal to activate alarms, fire pumps, or other safety mechanisms, alerting occupants and emergency responders to a potential fire. These switches are vital for ensuring the timely detection and response to fire incidents, helping to minimize damage and protect lives and property.

A Y strainer is a type of filtration device used in piping systems to remove debris and solid particles from flowing liquids. Its design features a Y-shaped body with a straining element (typically a perforated screen or mesh) positioned at an angle to the flow path. As the fluid passes through the strainer, the debris is trapped by the screen while the clean fluid continues its flow. Y strainers are commonly installed upstream of sensitive equipment, such as pumps, valves, and meters, to protect them from damage and maintain system efficiency. They are essential components for ensuring the integrity and reliability of fluid handling systems in various industrial, commercial, and residential applications.

Blazecut C-Series

Depending on the type of application the systems are supplied in various modifications such as:

- Type of System: DLP or ILP

- Type of Agent: FK-5-1-12, HFC-227ea, foam, powder

- Volume of cylinder: different volumes depending on type of extinguishing agent.

- Several detection options

- Components and installation material: distribution tubing, fittings, connectors, brackets

- Optional components: alarm panels, pressure switch, signaling devices, manual actuators, back up power units